Shotgun Chokes

The shotgun choke is defined by the amount of constriction within a shotgun bore to control the spread of the shot pellets. It was primarily developed to extend the shotgun's range and concentrate the shot pattern into a more dense area at specific areas. The continued development of the choke has made the shotgun an extremely efficient tool for the hunter, extending its range and killing power.

History Behind the Use of Shotgun Chokes

First, let’s look at the history of the shotgun choke. American ingenuity is attributed to the invention of the choke. In 1868, a patent for choke boring was issued to an American gunsmith named Sylvester Howard Roper. Although he was the first to be given a patent, it had been practiced many years before that.

Roper’s choke was very interesting in that it was detachable and screwed onto the end of the barrel. The barrel's exterior was threaded, and the muzzle device had a slight constriction that equaled that of a modified choke today. This device never caught on, partly due to the poor revolving shotgun design it was used on.

The famed W.W. Greener is credited with perfecting the choke and building reliable and consistent choked shotguns. Makers used many different techniques to achieve tighter patterns; however, the standard and cone style of chokes evolved into what we use today. Previous to the interchangeable choke, shotguns only had a fixed choke which is way less versatile.

How They Work

As mentioned before, a choke constricts the shot and concentrates the pattern downrange. As hundreds of shot pellets are being propelled down the barrel, they are typically held together by a plastic wad. This wad does a couple of things; it creates a gas seal to get the most out of your burning powder charge, it keeps the shot together while being propelled down the barrel, and lastly, it helps prevent some deformation as it is squeezed through the choke.

This “squeezing” effect is exactly why you shouldn’t shoot steel shot through extremely tight chokes. Steel is much harder than lead and does not compress like lead, sometimes resulting in a shotgun barrel that will bulge or worse, blow up.

Squeezing probably isn’t the right word, so we’ll continue using constriction instead. Experts have found that a change in a few thousandths of constriction significantly affects the overall pattern downrange, resulting in today’s line of choke tubes.

Choke Designs

Standard or English Choke

This type of choke has a slight constriction or cone near the end of the barrel, followed by a short parallel portion.

Cone or American Choke

Also known as a taper choke, the cone choke has a slight amount of constriction at the end of the barrel without the parallel section of the standard or English choke.

Swaged Choke

The swaged choke functions much like a cone choke but differs in that the exterior of the barrel is tapered as well. It is made by swaging the end of a standard shotgun barrel. These are often seen on the older budget break-open single-shots.

Recess or Jug Choke

Recess or jug choke involves the barrel being opened up or recessed near the muzzle, forming a “jug” near the end of the barrel. This has been done with a rod and emery cloth. This creates a section in the barrel for the shot to start to open up then be constricted before exiting the barrel.

Bell or Reverse Choke

The bell or reverse choke is the opposite of a cone choke in that the taper opens up the bore and is used to make extremely open patterns for short-range work.

Different Chokes & Their Uses

The choke is defined by the amount of constriction as compared to the size of the bore. Each manufacturer of choke tubes may have its own definition or amount of constriction for each choke, meaning an Improved cylinder of one brand might shoot a little different than another. However, this isn’t something to get hung up on.

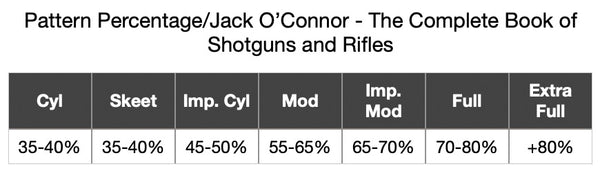

The standard choke sizes in the U.S. starting from widest spread to the tightest are; Cylinder, Skeet, Improved Cylinder, Modified, Improved Modified, Full, and Extra Full. Below are a couple of charts that show you what amount of constriction you can expect for each size and the percentage of the pattern that should fall in a 30-inch circle at 40 yards.

Choke Tube Chart

Which choke you choose to take out in the field is entirely up to you. This is one of the most argued subjects amongst wingshooters. While I have attached a chart to help you decide based on the game you are after, it is largely dependent on your shotgun, your load, and you, the shooter.

|

Choke |

Game Bird Species |

|

Turkey |

Extra-Full/Turkey Choke |

|

Quail |

Skeet |

|

Dove |

Improved Cylinder |

|

Duck |

Modified |

|

Pheasant |

Modified |

|

Goose |

Improved Modified |

|

Ruffed Grouse |

Improved Cylinder |

|

Plains Grouse |

Modified |

Your decision on the type of choke to use for a hunt should be dictated by the ranges you will be shooting at and the size of your shot. This chart is just a starting point for your decision. With all of this said, I hunt everything but turkey with a fixed Improved Cylinder choke and change my shot size and load based on the conditions. So once again, don’t get hung up on these or any other recommendations. Time spent at the range trumps all internet recommendations.

Pattern Your Choke

Even though your removable choke tubes are labeled with what amount of constriction they have, you still need to pattern them. Some shotguns and gauges can be picky depending on the amount of shot and type of shot you are using. For example, a 28 gauge with a full choke installed may pattern phenomenally with #5 shot, but with #4 shot, it may become inconsistent. Knowing exactly what your shot pattern is doing with a specific load will give you a complete understanding of your shotgun's performance.

Choke Maintenance

Now that we know all about what chokes are and how they are used, let’s look at maintaining them properly. Never change or maintain your chokes while the firearm is loaded!

There are very few tools needed for the proper maintenance of choke tubes. A decent choke tube wrench and firearms grease are all you need. The most common mistake with installing choke tubes is over-tightening them. The fine threads on choke tubes can be easily damaged and should not be over-torqued. Go a little further than finger tight to ensure it is good and snug.

You need to grease your chokes! Using Sage & Braker’s Firearm Grease, add a small dab to the threads of your choke before installing them. This little step will save you the embarrassment of a stuck choke tube. At the end of each hunting season, it is well worth it to remove your chokes, wipe them down, regrease the threads, and reinstall them. This takes less than 5 minutes and can save you a trip to the gunsmith.

A quick note on choke storage; because of their fine threads, they should be stored in a case or sleeve that doesn’t allow them to touch each other. Wipe them down with a light coating of CLP before putting them away, and they will last a lifetime.

Chokes Shouldn’t Be Complicated

Some gunsmiths have made careers out of perfecting the choke, but it shouldn’t be that complicated for the end-user. Keep it simple. If you are missing a lot of birds, try a more open choke. If you are wounding birds, try a tighter one. Having a shotgun with interchangeable chokes gives you a significant advantage in having a gun that can do it all, as long as the shooter does their part.

Written by Kurtis Martonik